Blanketing Valve

A blanketing valve is a device used to maintain a preset pressure within a tank or system. A typical use within the pharmaceutical sector is the use of a nitrogen blanketing valve to maintain an inert atmosphere within the tank.

- View All

- Actuation

- Chillers

- Heat Exchangers

- Instrumentation & Control

- Mechanical Seal

- Mixing Technology

- Other

- Process Equipment

- Pumps

- Sight Glasses

- Software

- Steam Systems

- Tank & Pipeline Ancillaries

- Tank Venting

- Valves

Product categories

-

Tank VentingCashco

ULR-1 Pressure Reducing Regulator with Unloader

-

Tank VentingCashco

1000 HP Basic, Cryogenic, SF

-

Tank VentingCashco

DA1 Pressure Reducing Regulator- Spring Operated

-

Tank VentingCashco

1088 Vacu-Gard® Tank Blanketing Valve (DN15)

-

Tank VentingCashco

SAP Ultra High Purity Pressure Reducing Regulator Piston-Operated

-

Tank VentingCashco

P4 Balanced Pressure Reducing Regulator

-

Tank VentingCashco

5381 Pressure Reducing Regulator

-

Tank VentingCashco

C-PRV Pressure Reducing Regulator

-

Tank VentingCashco

1078 Vacu-Gard Tank Blanketing Valve

-

Tank VentingCashco

PGR-1 Pilot Operated Pressure Reducing Regulator Pressure Loaded Diaphragm

-

Tank VentingCashco

POSR-2 PRESSURE REDUCING REGULATOR – PILOT OPERATED

What does it mean when a tank is blanketed?

Tank blanketing, or padding, is the process and practice of covering a stored commodity, usually a liquid, with a gas. It is the best prevention of and protection against explosions. If the commodity is volatile or toxic, tank blanketing can prevent it from harming workers, equipment and the environment. When the commodity is a food or other substance, blanketing protects it from oxidation or contamination though exposure to air or moisture.

What is the purpose of nitrogen blanketing?

In a lot of applications, there are flammable solvents present and by using nitrogen blanketing you create an inert atmosphere to substantially reduce the risk of explosion.

What is a typical nitrogen blanketing design?

Nitrogen blanketing valves allow low pressure nitrogen into the vessel when it is being emptied or if there are losses through normal venting during the reaction.

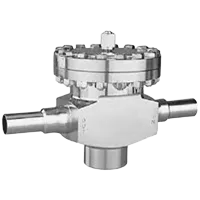

An example from our brand partners Cashco, the Model 1078 is a pilot operated blanketing valve allowing tanks to be controlled with much tighter tolerances than before. The unit has multiple flow plugs, sensing configurations, and body configurations in order to meet the specific needs of the end user.

What is a pilot operated blanketing valve?

A pilot valve is a small valve that controls a limited-flow control feed to a separate piloted valve. Typically, this valve controls a high pressure or high flow feed. Pilot valves are useful because they allow a small and easily operated feed to control a much higher pressure or higher flow feed, which would otherwise require a much larger force to operate; indeed, this is even useful when a solenoid is used to operate the valve. Pilot valves are often used in critical applications (e.g., emergency and safety controls) and are human-operated. They can be set up as a push-to-activate or dead man’s switch.

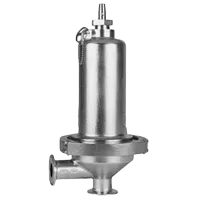

What is a high purity blanketing regulator?

These are blanketing valves used with sanitary design in food and pharmaceutical applications

What is a high capacity tank blanketing valve?

This is a valve that will allow larger volumes of gas into the system/tank.

Which tank blanketing regulators does Flexachem supply?

Flexachem are the localised support within Ireland for the globally installed brand Cascho. We supply a wide range of pilot operated blanketing valves, low pressure to medium pressure blanketing valves and high purity blanketing regulators for sanitary applications.

If you have a specific requirement in mind, please contact one of our product specialists to discuss your application.

Do you have questions or comments about receiving a quote, our products, solutions and services, and support? Contact us by filling out the form.

- Stephen White - Mob: 083 165 3830

- Brendan Merrigan (External) – Mob: 087 2598124

- Office Tel: 021 461 7200