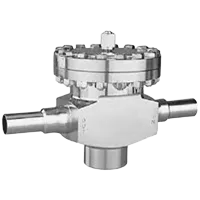

SAP Ultra High Purity Pressure Reducing Regulator Piston-Operated

Tank Venting

Cashco

Send Enquiry

The SAP Ultra High Purity Pressure Reducing Regulator is a high-performance, dome-loaded, piston-style regulator designed for ultra-high purity fluids and gaseous service. It features an internal pressure balancing piston-cylinder that offers medium flow capacity and high pressure drop capability. The regulator is suitable for electronic-grade and other ultra-pure fluids, with a robust construction for high-pressure applications and in-line maintenance.

- Specifications

- Technical Data

- Advantages

- Industries

- Applications

- Contact

Specifications

- Sizes: 3/4”, 1”, 2”, 3”, 4” (DN20, 25, 50, 80, 100)

- Maximum Inlet Pressure: Up to 3000 psig (207 Barg) — dependent on body size and elastomeric materials.

- Outlet Pressure Range: 5 – 600 psig (0.34 – 41.4 Barg) — maximum available controlled pressure varies with body size.

- Temperature Range: -20 to +400° F (-29° to +204° C) — dependent on elastomeric materials.

Technical Data

- Wetted Trim Materials: All stainless steel (SST)

- Body Finish: Standard -15 μ-in Ra average surface finish; optional 10 μ-in Ra average surface finish available for Barstock body only.

- Construction: Electro-polished, tube-end connections, capable of withstanding a full vacuum.

- Cryogenic Construction: Available upon consultation with the factory.

Advantages

- High Pressure Capability: Handles up to 3000 psig (207 Barg) for demanding applications.

- Electro-polished Finish: Ensures superior cleanliness and reduces contamination risk.

- In-Line Maintenance: Facilitates easy servicing without system disassembly.

- Versatility: Suitable for a wide range of ultra-high purity fluids and gases.

Industries

- Electronic Grade Fluids: Ideal for applications requiring ultra-high purity standards.

- High-Purity Gas Handling: Effective for gases such as oxygen, nitrogen, hydrogen, helium, and argon.

- Cryogenic Applications: Suitable for extremely low-temperature environments (consult factory for specific requirements).

Applications

- Electronic Grade Fluids: Maintains pressure control for ultra-pure and electronic-grade fluids.

- Gaseous Service: Used in systems requiring high purity gases.

- Cryogenic Systems: Applicable in environments requiring cryogenic construction (consult factory for details).

Do you have questions or comments about receiving a quote, our products, solutions and services, and support? Contact us by filling out the form.

- Michael Bradley (External) – Mob: 086 047 6178

- Brendan Merrigan (External) – Mob: 087 2598124

- Stephen White - Mob: 083 165 3830

- Office Tel: 021 461 7200

-

PumpsNETZSCH

PumpsNETZSCHProgressive Cavity Pump

-

PumpsFlowserve

PumpsFlowserveSIHI SuperNova Pump ZDN – Hot Water

-

PumpsNETZSCH

PumpsNETZSCHMulti Screw Pump

-

PumpsFlowserve

PumpsFlowserveMark 3 Recessed Impeller Pump

-

Mixing TechnologyChemineer

Mixing TechnologyChemineerChemineer HS Turbine Agitators

-

Mixing TechnologyGreerco

Mixing TechnologyGreercoGreerco Pipeline Mixers

-

PumpsFlowserve

PumpsFlowserveDurco Mark 3 Pump – ANSI/ASME standard