Single Mechanical Seal

A single mechanical seal is a type of mechanical seal which consists of one primary seal and it seals from process to atmosphere. There is always some leakage either to atmosphere or into process depending on the process pressure.

- View All

- Actuation

- Heat Exchangers

- Instrumentation & Control

- Mechanical Seal

- Mixing Technology

- Other

- Process Equipment

- Pumps

- Sight Glasses

- Software

- Steam Systems

- Tank & Pipeline Ancillaries

- Tank Venting

- Valves

-

Mechanical SealFlowserve

Split Seal (MSS)

-

Mechanical SealFlowserve

Standard Cartridge Seal ISC2 Series

Some factors to consider when selecting a Single Mechanical Seal;

- it is a controlled leakage device i.e. very low leakage (weepage) seal

- Process pressurised = leakage from process to atmosphere

- Process under vacuum = leakage from atmosphere to process.

- Found as Wet-running (liquid phase between sealing faces) on liquid pumps, Dry-running (gaseous phase between sealing faces) on blowers/compressors/mixers.

- Not recommended if leakage of product to environment is an issue i.e. these are not 100% containment devices.

- Not recommended if contamination of product by environment is an issue.

- Under Atex (for dry running) there are limits on speed and operating parameters.

- Most economical seal.

- Nearly always dry running contacting seal (mechanical seal face wear) for top mounted mixers. For side and bottom mounted (seal is submerged) a wet-running seal is normally specified.

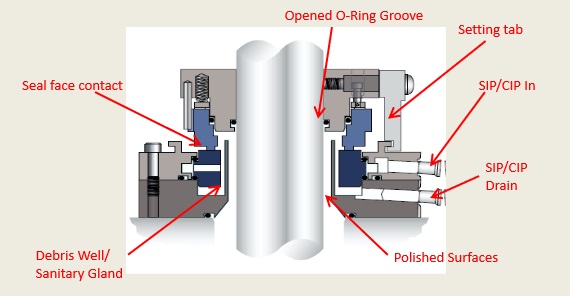

- Debris well can be fitted to catch visible particles on mixers.

- Various seal plans can be fitted for better operation on pumps see flush/quench plans

Flexachem offer a full range of Flowserve Single Mechanical Seals:

Standard Cartridge Seal for pumps and mixers – ISC2 Series

Single Seal for top-mounted mixers – VRA

Split Seal for mixers/pumps – MSS/PSS III

If you have any query around how to install a single mechanical seal for agitators or mixers or have some concerns around the seal failures, why not contact one of our mechanical seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process back up and running reliably again.

Do you have questions or comments about receiving a quote, our products, solutions and services, and support? Contact us by filling out the form.

- Chris Sheeran (External) – Mob: 087 755 9936

- Evan Twomey - 083 162 0251

- Miriam Adair - Tel: 021 461 7235

- Office Tel: 021 461 7200