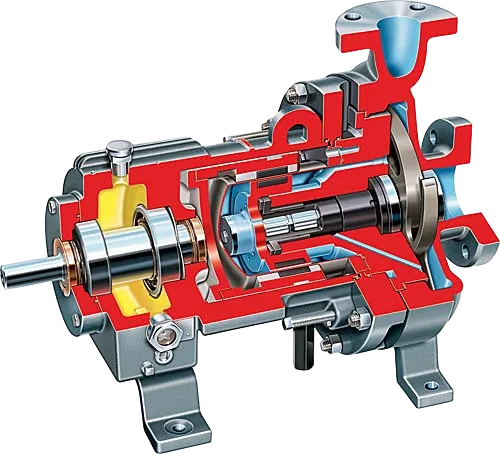

Guardian ANSI Overhung Magnetic Drive Pump

Pumps

Flowserve

Send Enquiry

The Flowserve Guardian ANSI Overhung Magnetic Drive Pump is a horizontal, magnetic drive pump, compliant with ANSI B73.1M dimensional standards. The Guardian is designed for simplicity and reliability for emission-free service requirements. The Guardian pump uses a Mark 3 casing and impeller for proven, consistent hydraulic performance. The Guardian magnetic drive pump possesses numerous reliability and performance-enhancing features including:

- Rugged silicon carbide bushings and journals

- Proven Mark 3 casing and impeller

- Optimized internal lubrication path

- Available in 18 sizes, the Guardian uses the same casing and reverse vane impeller as the Flowserve Durco Mark 3 ANSI standard pump. This interchangeability of wet end parts provides consistent hydraulic performance and allows pumps to easily be converted from sealed to sealless configurations.

- Specifications

- Technical Data

- Advantages

- Industries

- Applications

- Documents

- Contact

Specifications

Configurations:

- G-Series (-75°C [-100°F] to 120°C [250°F])

- H-Series (-120°C [-250°F] to 290°C [550°F])

Choice of materials:

- 316 SS

- Alloy 20

- Hastelloy® C-276

- Hastelloy® B2

- Titanium

Options:

- Fiber-optic leak detection

- Containment shell temperature probes

- Process temperature probes

- External flush plans

- Pressure transducers

- Flow switches

- Vibration probes

Technical Data

Operating parameters:

- Flows to 375 m³/h (1650 gpm)

- Heads to 215 m (705 ft)

- Temperatures from -75°C (-100°F) to 290°C (550°F)

Advantages

- Mark 3 Casing and Impeller: Deliver consistent hydraulic performance and maximum interchangeability.

- Reverse Vane Impeller: Provides constant inner bearing lubrication, predictable thrust characteristics, and lowest average NPSHR.

- Optimized Internal Lubrication Path: Designed to provide bearing lubrication before heat removal from containment area.

- Silicon Carbide Bushings and Journals: With double spiral grooves for superior lubrication and bearing life.

- Precise Running Clearances: Protect the containment shell from potential damage.

- External Flush Plan: Available with the Guardian to extend the pump’s application range. By introducing a clean, compatible flush fluid or a filtered bypass flush into the containment shell area, the Guardian can handle otherwise difficult process conditions.

Industries

- Electronics

- Acid Transfer

- Volatile Organic Compounds

- Pharmaceuticals

- Automotive and Aircraft

- Solvents

- Caustic and Chlor-Alkali

Applications

- Polymers

- Solvents

- Toxic Services

- Ultrapure Liquids

- Valuable Liquids

- Water Treatment

- Organic Chemicals

- Emissions Reduction

- Difficult-to-Seal Liquids

- Corrosive Services

- Chlor-alkali

- Acid Transfer

- Aquariums

- Flammable Liquids

Contact our Pump Specialist Team

- Andrew Bishop - tel: 083 089 1204

- Phil Soltan (External) – mob: 086 185 3782

- Adrian McSweeney – tel: 021 461 7212

- Paul-Fox Morris – tel: 021 461 7231

- Una Long (Pump & Service Support) – tel: 021 431 7200

- Tel: 021 461 7200

-

PumpsNETZSCH

PumpsNETZSCHProgressive Cavity Pump

-

PumpsFlowserve

PumpsFlowserveSIHI SuperNova Pump ZDN – Hot Water

-

PumpsNETZSCH

PumpsNETZSCHMulti Screw Pump

-

PumpsFlowserve

PumpsFlowserveMark 3 Recessed Impeller Pump

-

Mixing TechnologyChemineer

Mixing TechnologyChemineerChemineer HS Turbine Agitators

-

Mixing TechnologyGreerco

Mixing TechnologyGreercoGreerco Pipeline Mixers

-

PumpsFlowserve

PumpsFlowserveDurco Mark 3 Pump – ANSI/ASME standard